Steam consumption optimization is an ongoing challenge in utilities. As a key cost driver not only is steam acquisition and use to be closely monitored, plant managers must also aim to ensure that it is 100% dry saturated to efficiently maximize heat transfer to core processes while protecting the heat exchanger, pipework and instrumentation from wetness and pressure spikes. Endress+Hauser technologies and expertise can enable these multiple imperatives to be met.

Key facts

90%

Dryness fraction results in 5% additional measuring error in volume and mass with traditional DP and vortex meters, and 10% lost energy

Accurate, reliable measurement of all process variables

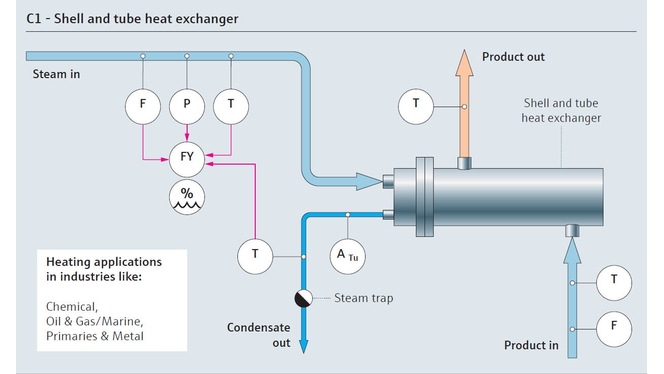

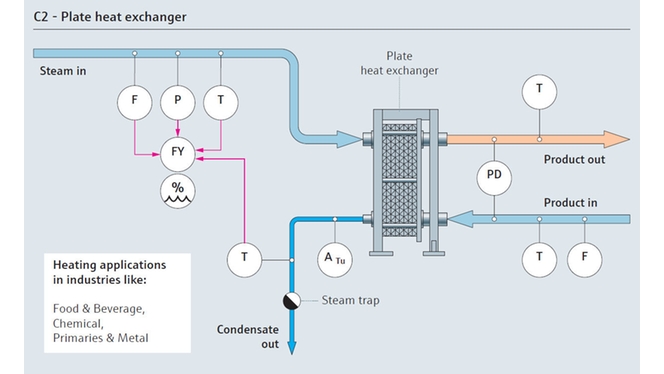

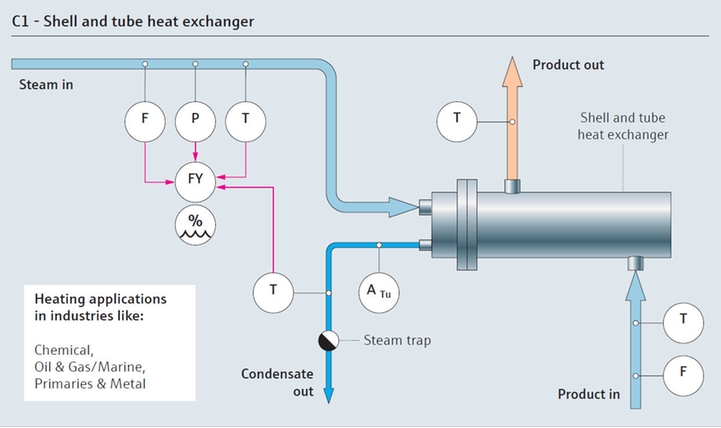

The efficient use of steam in any industrial process depends upon the accurate measurement and monitoring of multiple process parameters.

Our expertise in the field

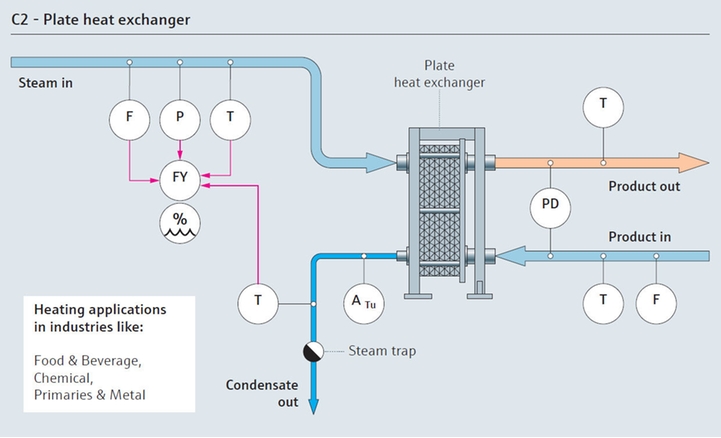

Offering a comprehensive portfolio of measurement instrumentation for all steam process variables including flow, pressure, temperature, analysis, and level, Endress+Hauser helps ensure heat from steam is efficiently applied to your processes.

- Detect wet steam and measure the dryness fraction with a calculation of steam mass and energy using the multivariable Vortex flowmeter Proline Prowirl F 200

- Monitor steam supply pressure with sensors such as the Cerabar M PMP51

- Check steam supply temperature with our robust Pt100 resistance line of weld-in Omnigrad thermometers (TR15 and TH15)

- Determine condensate quality with our Turbimax family of turbidity sensors, or with conductivity sensors Condumax, to know if condensate can be reused to reduce cost of chemicals

Heat exchanger and product protection

Heat exchangers can be vulnerable to breakthroughs, and the resultant direct contact with the steam presents risks both to personnel and to products.

Our expertise in the field

Endress+Hauser technologies enable both enhanced protection of heat exchangers, and rapid intervention in case of any failure.

- Determine if heat transfer surfaces are broken using condensate turbidity verification with our Turbimax sensors

- Maximize availability and minimize production losses with immediate problem detection

- Check steam dryness fraction at the heat exchanger inlet to reduce the risk of heat exchanger damage or destruction from water hammer

Heat exchanger efficiency verification

Heat exchanger efficiency can be compromised both by the build-up of magnetite or other materials on the steam side, and by the build-up of degenerated product on the product side, with significant impact on cost effectiveness.

Our expertise in the field

Endress+Hauser Memograph M offers an energy and application data manager for real-time monitoring and visualization of heat exchanger consumption and energy performance.

- Monitor heat exchanger performance in real time

- Rapidly detect drift in heat exchanger efficiency

- Optimize interventions for maximum production efficiency and reliability

.jpg)

Energy measurement proving

A key challenge for utilities plant managers is to ensure that the measurements used to determine the efficiency of steam consumption are reliable.

Our expertise in the field

Endress+Hauser offers an Energy Measurement Proving Service to check and confirm the accuracy of steam consumption efficiency measurements. As well as checking all components in the energy measurement loop and giving clear recommendations on how to improve measurement accuracy, our technical experts will perform on-site calibration and verification of your field devices with minimum or no process interruptions.

- Rely on proven accuracy of steam measurements throughout the energy measurement loop

- Optimize your steam consumption and quality for improved production efficiency

- Reduce downtime and improve safety with early identification of problems

Benefits

A deep understanding of energy and utility management and your daily challenges lies at the heart of our product and service offering for steam. We bring a comprehensive portfolio of accurate and reliable measurement instrumentation for all process variables, together with services and solutions that give you complete transparency and ensure compliance with energy and environmental management standards. Choose Endress+Hauser for safe, available, transparent and efficient steam consumption.

Key facts

5 to 15%

typical energy consumption savings from comprehensive energy monitoring solutions

Key facts

24/7

operational safety throughout the entire life cycle of the steam system

Key facts

>60

years of experience in utilities

How we can help

From enabling unrivaled accuracy in measurement of steam consumption, to supporting in determining the most relevant efficiency KPIs, Endress+Hauser is your partner of choice for optimal steam management. Our comprehensive range of measurement instrumentation and monitoring systems ensures that steam reaches your processes 100% dry saturated for efficient heat transfer and optimal equipment safety.

- Ensure the accurate mass and energy balance of your steam system with correct measurements, compensated inline by the dryness fraction using 2-wire technology

- Comply with energy management (ISO 50001) and environmental management (ISO 140001) standards using Endress+Hauser instrumentation with in-built diagnostics, verification, and monitoring (Heartbeat Technology)

- Directly measure wet and dry steam compensated as per international standards (IAPWS- IF97/ASME)

- Direct measurement of wet and dry steam compensated as per international standards IAPWS- IF97/ASME

- Check and improve efficiency by monitoring the energy passed to the process