Overzicht specificaties

Process temperature

0 to 140 °C (32 to 284 °F)

Process pressure

0 to max. 4 bar (0 to max. 58 psi) overpressure for manual actuation

Toepassingsgebied

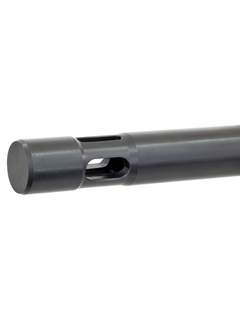

De Cleanfit CPA472D-armatuur is ontworpen voor zware procesomstandigheden. Dankzij de vele robuuste materialen werken uw sensoren veilig, zelfs onder hoge druk, bij hoge temperaturen of in agressieve media. Met deze armatuur kunt u sensoren vervangen zonder procesonderbrekingen en deze automatisch reinigen en kalibreren via het optionele regelsysteem. Profiteer van eenvoudige, tijdbesparende sensorbediening en een lange levensduur van de sensoren.

De Cleanfit CPA472D is bedoeld voor installatie in tanks en pijpleidingen in:

Chemische industrie

Elektriciteitscentrales

Biodiesel-installaties

Het instrument is geschikt voor gebruik met drukken tot 10 bar.

Voordelen

Extreem robuust: geschikt voor gebruik met drukken tot 10 bar en temperaturen tot 140 °C, zelfs als PEEK-, PVDF- en geleidende PVDF-uitvoeringen

Maximale chemische weerstand waarborgt een lange levensduur

Geen procesonderbrekingen voor elektrodereiniging en -kalibratie – bespaart onderhoudstijd en -kosten

Flexibele aanpassing aan alle toepassingen door grote diversiteit van materialen en procesaansluitingen

Succesverhalen

Meetbaar en testbaar: monitoren met Teqwave

Een efficiënte reiniging van onderdelen is een belangrijk onderdeel van de productie van industrieel vervaardigde componenten. Borer Chemie AG vertrouwt daarom op de concentratiemeting met Teqwave F, I en T.

Lees het hele verhaal

Liquid analysis in LNG trains

The various process steps in a gas liquefaction plant must comply with different limit values. Our products are ideally suited for these processes.

Lees het hele verhaal

Eenvoudige producten

Gemakkelijk te selecteren, installeren en gebruiken

Technische topkwaliteit

Eenvoud

Standaardproducten

Betrouwbaar, robuust en onderhoudsarm

Technische topkwaliteit

Eenvoud

High-end producten

Functioneel en uiterst doelmatig

Technische topkwaliteit

Eenvoud

Technische topkwaliteit

Eenvoud

FLEX selectie

Technische topkwaliteit

Eenvoud

Fundamental selectie

Voldoe aan uw basismeetvoorwaarden

Technische topkwaliteit

Eenvoud

Lean selectie

Beheers eenvoudig uw belangrijkste processen

Technische topkwaliteit

Eenvoud

Extended selectie

Optimaliseer uw processen met innovatieve technologieën

Technische topkwaliteit

Eenvoud

Xpert selectie

Beheers uw meest uitdagende applicaties

Technische topkwaliteit

Eenvoud

Ook interessant voor u

Over ons

Geen armatuur, geen meting!

De veiligheid en het bedieningsgemak van een analytische meetpunt begint met het gebruik van het juiste armatuur. Onze flexibele armatuurproductie zorgt ervoor dat u het juiste armatuur voor uw behoeften krijgt.

Meer informatie

Application

Chemical industry, biodiesel plants, power plants, plant design, tanks, process vats or pipes

Characteristic

For tanks and process vats and pipelines or pipes (min. DN80)

Material

Electrode holder, rinse chamber and raised face:

Dimension

Immersion depth: 146 or 280 mm (5.75 or 7.87 inch)

Process temperature

0 to 140 °C (32 to 284 °F)

Process pressure

0 to max. 4 bar (0 to max. 58 psi) overpressure for manual actuation

Connection

Process connections: Flange DN 50, DN 80, ANSI 2", JIS IS10K50A, internal thread G1¼

Application

Chemical industry, biodiesel plants, power plants, plant design, tanks, process vats or pipes

Characteristic

For tanks and process vats and pipelines or pipes (min. DN80)

Material

Electrode holder, rinse chamber and raised face:

Dimension

Immersion depth: 146 or 280 mm (5.75 or 7.87 inch)

Process temperature

0 to 140 °C (32 to 284 °F)

Process pressure

0 to max. 4 bar (0 to max. 58 psi) overpressure for manual actuation

Connection

Process connections: Flange DN 50, DN 80, ANSI 2", JIS IS10K50A, internal thread G1¼

11 documenten

Technical Information

Cleanfit P CPA472D

Retractable process assembly for pH, ORP and other industry electrodes

EN

NL

Duits French Italiaans Chinees

08/10/2013

01/06/2010

01/05/2006

Taal:

Engels

Versie:

08/10/2013

Bestandsgrootte:

940.5 KB

Bestandsnaam:

TI00403CEN_1313.pdf

Technical Information Topcal S CPC310

Fully automatic measuring, cleaningand calibration system in hazardous

EN

NL

Duits French Italiaans Pools Russisch

22/07/2015

01/07/2006

Taal:

Engels

Versie:

22/07/2015

Bestandsgrootte:

2 MB

Bestandsnaam:

TI00404CEN_1315.pdf

Operating Instructions

Cleanfit CPA472D

Retractable Process Assembly

EN

NL

Tsjechisch Duits French Italiaans Japans Pools

08/10/2013

01/09/2010

01/05/2006

Taal:

Engels

Versie:

08/10/2013

Bestandsgrootte:

1.3 MB

Bestandsnaam:

BA00403CEN_1313.pdf

pH measurement in industrial processes

Selection and engineering guide for different industries and

Taal:

Engels

Versie:

02/12/2021

Bestandsgrootte:

3.2 MB

Bestandsnaam:

CP00010CEN_1621_pH selection guide_2021.pdf

さまざまな産業およびアプリケーション向けのpH測定セレクションガイド

Taal:

Japans

Versie:

08/02/2024

Bestandsgrootte:

5.8 MB

Bestandsnaam:

pH selection guide_CP00010C.pdf

pH-Messung in Industrieprozessen

Auswahl- und Engineering-Hilfe für verschiedene Industriebranchen und

Taal:

Duits

Versie:

01/12/2021

Bestandsgrootte:

3.3 MB

Bestandsnaam:

CP00010CDE_1621_pH Auswahlhilfe_2021.pdf

L’automatisation des process vaut son pesant d’or

Memosens Les sondes de pH améliorent les process chez Agnico Eagle

Taal:

French

Versie:

01/07/2016

Bestandsgrootte:

673.1 KB

Bestandsnaam:

CS01496CFR-0216-Agnico Eagle.pdf

Process automation worth its weight in gold

Memosens pH sensors improve processes at Agnico Eagle

Taal:

Engels

Versie:

01/07/2016

Bestandsgrootte:

1.5 MB

Bestandsnaam:

CS01496CEN_0116_Agnico Eagle goldmine.pdf

Prozessautomatisierung, die Gold wert ist

Memosens pH-Sensoren verbessernProzesse bei Agnico Eagle

Taal:

Duits

Versie:

01/07/2016

Bestandsgrootte:

1.5 MB

Bestandsnaam:

CS01496CDE_0116_Agnico Eagle Goldmine.pdf

Product family: CleanFit P

Product root: CPA472D-

Taal:

Engels

Versie:

14/08/2020

Bestandsgrootte:

187.9 KB

Bestandsnaam:

CPA472D_HE Ex_HE_01324_01.20.pdf

Zoek reservedelen op nummer in tekening

60 spare parts & accessories

60 spare parts & accessories

60 spare parts & accessories

Kit CPA472D-KCl: Exit air seal bush PVDF

CPA472D afdichting niet medium cont.

Tekeningnummer

Bestelcode

6

71024454

CPA472D Seals flange inside Kalrez

Tekeningnummer

Bestelcode

10

71211749

CPA472D afd. set flens binnen in Viton

Tekeningnummer

Bestelcode

10

71211751

CPA472D Seal set flange inside EPDM

Tekeningnummer

Bestelcode

10

71211752

CPA472D seal set G1 1/4" inside EPDM

Tekeningnummer

Bestelcode

10

71211736

CPA472D seal set G1 1/4" inside Viton

Tekeningnummer

Bestelcode

10

71211745

CPA472D seal set G1 1/4 inside Kalrez

Tekeningnummer

Bestelcode

10

71211748

CPA472D flensafd. Viton mediumcont.

Tekeningnummer

Bestelcode

10

71024242

Sealings set CPA472D Viton

Tekeningnummer

Bestelcode

10

71027299

CPA472D Seals flens Kalrez mediumcont.

Tekeningnummer

Bestelcode

10

71024247

Sealings set CPA472D Kalrez

Tekeningnummer

Bestelcode

10

71027302

CPA472D Seals flange EPDM mediumcont.

Tekeningnummer

Bestelcode

10

71043257

Sealings set EPDM for CPA472D G1 1/4"

Tekeningnummer

Bestelcode

10

71043259

Kit CPA472/D: 20 pcs. O-ring ID14 W3 FPM

Tekeningnummer

Bestelcode

10

71090063

Kit CPA472/D: 2 pcs.O-ring ID14W3 KALREZ

Tekeningnummer

Bestelcode

10

71090065

Kit CPA472D Rinse chamber, IN, 316Ti,G,G

Tekeningnummer

Bestelcode

9

71214026

Onderdelen CPA871, alle materialen

Kit CPA472D Rinse chamber, IN, Alloy,G,G

Tekeningnummer

Bestelcode

9

71214033

Kit CPA472D Rinse chamber, IN, 316Ti,G,N

Tekeningnummer

Bestelcode

9

71214227

Kit CPA472D Rinse chamber, IN, Alloy,G,N

Tekeningnummer

Bestelcode

9

71214228

Kit CPA472D Rinse chamber, IN, PEEK, F,G

Tekeningnummer

Bestelcode

20

71214230

Kit CPA472D Rinse chamber, IN, PVDF,F,G

Tekeningnummer

Bestelcode

20

71214232

Kit CPA472D Rinse chamber, IN,PVDF-C,F,G

Tekeningnummer

Bestelcode

20

71214233

Kit CPA472D Rinse chamber, IN, 316Ti,F,G

Tekeningnummer

Bestelcode

20

71214234

Kit CPA472D Rinse chamber, IN, Alloy,F,G

Tekeningnummer

Bestelcode

20

71214235

Kit CPA472D long, 361Ti, D18-I: Sensorg

Tekeningnummer

Bestelcode

7

71214236

Kit CPA472D long, Alloy, D18-I: Sensorg

Tekeningnummer

Bestelcode

7

71214237

Kit CPA472D short, 361Ti, D18-I: Sensorg

Tekeningnummer

Bestelcode

7

71214238

Kit CPA472D short, Alloy, D18-I: Sensorg

Tekeningnummer

Bestelcode

7

71214239

Kit CPA472D long, 316Ti, D25-I: Sensorg

Tekeningnummer

Bestelcode

7

71214240

Kit CPA472D long, Alloy, D25-I: Sensorg

Tekeningnummer

Bestelcode

7

71214242

Kit CPA472D short, 361Ti, D25-I: Sensorg

Tekeningnummer

Bestelcode

7

71214243

Kit CPA472D short, Alloy, D25-I: Sensorg

Tekeningnummer

Bestelcode

7

71214244

Kit CPA472D long, PEEK, D25-I: Sensorg

Tekeningnummer

Bestelcode

7

71214245

Kit CPA472D short, PEEK, D25-I: Sensorg

Tekeningnummer

Bestelcode

7

71214246

Kit CPA472D long, PVDF, D25-I: Sensorg

Tekeningnummer

Bestelcode

7

71214247

Kit CPA472D short, PVDF, D25-I: Sensorg

Tekeningnummer

Bestelcode

7

71214248

Kit CPA472D long, PVDF-C, D25-I: Sensorg

Tekeningnummer

Bestelcode

7

71214249

Kit CPA472D short,PVDF-C, D25-I: Sensorg

Tekeningnummer

Bestelcode

7

71214250

KIT CPA472D man.long Gel:retract.pipe

Tekeningnummer

Bestelcode

1

71026649

KIT CPA472D long pneum. Gel: retr. pipe

Tekeningnummer

Bestelcode

1

71026651

KIT CPA472D short hand Gel: retr. pipe

Tekeningnummer

Bestelcode

1

71026652

KIT CPA472D short pneum. Gel: retr. pipe

Tekeningnummer

Bestelcode

1

71026653

Kit CPA472D KCI-pipe manual

Tekeningnummer

Bestelcode

16

71102512

Kit CPA472D KCi-pipe pneumatic

Tekeningnummer

Bestelcode

16

71102513

KIT CPA472D long: Cylinder 1.4404 w.head

Tekeningnummer

Bestelcode

5

71026656

KIT CPA472D short: Cylinder1.4404 w.head

Tekeningnummer

Bestelcode

19

71026658

KIT CPA472D with flange: flange DN50

Tekeningnummer

Bestelcode

23

71026774

KIT CPA472D with flange: flange ANSI 2"

Tekeningnummer

Bestelcode

23

71026776

KIT 472D DN50+ANSI 2", PEEK: raised face

Tekeningnummer

Bestelcode

22

71026766

KIT 472D DN50+ANSI 2", PVDF: raised face

Tekeningnummer

Bestelcode

22

71026767

KIT 472D DN50+ANSI 2"PVDF-c: raised face

Tekeningnummer

Bestelcode

22

71026768

KIT 472D DN50+ANSI 2", HC4: raised face

Tekeningnummer

Bestelcode

22

71026770

KIT 472D DN50+ANSI 2",1.4571:raised face

Tekeningnummer

Bestelcode

22

71026772

KIT CPA472D with flange: flange DN80

Tekeningnummer

Bestelcode

23

71026775

KIT CPA472D DN80 PEEK: raised face

Tekeningnummer

Bestelcode

22

71026781

KIT CPA472D DN80 PVDF: raised face

Tekeningnummer

Bestelcode

22

71026783

KIT CPA472D DN80 PVDF-cond: raised face

Tekeningnummer

Bestelcode

22

71026784

KIT 472D DN80 HC4: raised face

Tekeningnummer

Bestelcode

22

71026785

KIT CPA472D DN80 1.4571: raised face

Tekeningnummer

Bestelcode

22

71026787

KIT CPA472D with flange: JIS flange

Tekeningnummer

Bestelcode

23

71085857

KIT 472D JIS flange, PEEk: raised face

Tekeningnummer

Bestelcode

22

71085850

KIT 472D JIS flange, PVDF: raised face

Tekeningnummer

Bestelcode

22

71085851

KIT 472D JIS flange, PVDF-C: raised face

Tekeningnummer

Bestelcode

22

71085852

KIT 472D JIS flange, HC4: raised face

Tekeningnummer

Bestelcode

22

71085854

KIT 472D JIS flange, 316TI: raised face

Tekeningnummer

Bestelcode

22

71085856

Kit CPA472D/473: 20retaining washer

Tekeningnummer

Bestelcode

18

71103282

KIT 472D HC4, G1/4": Swagelok rinse conn

Tekeningnummer

Bestelcode

21

71026794

KIT 472D 1.4571 G1/4: Swagelok rinse con

Tekeningnummer

Bestelcode

21

71026796

KIT CPA471 LUCHTSPOEL, DUMMY PLUG SS

Tekeningnummer

Bestelcode

2.8

51503732

KIT CPA47X: Throttel check valve

Tekeningnummer

Bestelcode

2

71329949

KIT CPA: elbow conn. R1/8 OD6 SS 2 pcs.

Tekeningnummer

Bestelcode

3

71027935

Tekeningnummer

Bestelcode

11

51503733

Tekeningnummer

Bestelcode

4

51503731

KIT CPA472D: cyl. screw M6x70 20 pcs.

Tekeningnummer

Bestelcode

15

71026789

Kit CPA471/472 cil.schroef M6x45 20 st.

Tekeningnummer

Bestelcode

17

51503738

Kap tegen spatwater voor armaturen

Tekeningnummer

Bestelcode

25

51517522

Slanggeleider KCL (grijs)

Tekeningnummer

Bestelcode

26

51518182

Slang support voor Ø6 en Ø8 KCL slang

Protective sleeve wide f. KCl-electr.

Tekeningnummer

Bestelcode

27

50080430

Pneumatische eindschakelaar (2st)

Tekeningnummer

Bestelcode

12

51502874

KIT CPA47x electr. proxim.switches

Tekeningnummer

Bestelcode

13

51502873

Built-in adapt.straight,Size25,1.4404

Built-in adapt.oblique,Size 25,1.4404

flens- lassen contactdoos DN50, PN16

Dummy plug 316L, G 1 1/4 inch internal

Locking screw G1/4 inch GL8mm

CPA472 slangset (2 stuks) G¼ DN12, PVDF

KIT CPA47x pneu.connection G1/8 AD6 10p

Wij letten op uw privacy

We maken gebruik van cookies om uw browse-ervaring te verbeteren, statistische gegevens te verzamelen om de site-functionaliteit te optimaliseren en om reclame of content op maat te presenteren.

Door "Accepteer alles" te selecteren gaat u akkoord met ons gebruik van cookies.cookie-richtlijnen .

Aanpassen

Alleen het essentiële accepteren

Accepteer alles