%20-%20PP01.jpg)

Overzicht specificaties

-

Max. meetfout

Mass flow: ±0.5 % of batch

-

Measuring range

0 to 150 kg/min (0 to 330 lb/min)

-

Medium temperature range

–50 to +125 °C (–58 to +257 °F)

-

Max. process pressure

350 bar (5080 psi)

-

Wetted materials

Measuring tube: 1.4435 (316L)

Connection: 1.4404 (316/316L)

Toepassingsgebied

De markt voor aardgas groeit nog steeds! Samengeperst aardgas is inmiddels een alternatieve brandstof voor voertuigen. Samengeperst aardgas wordt ook beschouwd als de schoonste brandstof voor verbrandingsmotoren. De nieuwe CNGmass is speciaal ontworpen voor dispensers. Met deze coriolis-flowmeter kan de massaflow met maximale nauwkeurigheid worden gemeten — onafhankelijk van druk en temperatuur.

Meting wordt niet beïnvloed door fysische vloeistofeigenschappen, zoals viscositeit of dichtheid

Nauwkeurige meting van samengeperst aardgas (CNG) in hogedruk-tanktoepassingen.

Eigenschappen instrument

Flows tot 150 kg/min (330 lb/min)

Procesdruk tot 350 bar (5080 psi)

Breekplaat beschikbaar

Robuuste, compacte transmitterbehuizing

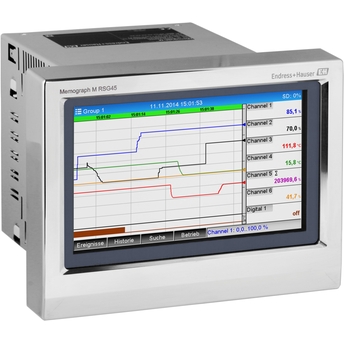

Modbus RS485

Ontworpen voor alle toepassingsbehoeften

Voordelen

Uitstekende operationele veiligheid – betrouwbaar onder extreme procesomstandigheden

Minder procesmeetpunten – multivariabele meting (flow, dichtheid, temperatuur)

Ruimtebesparende installatie – geen in-/uitlaatlengten

Ruimtebesparende transmitter – volledige functionaliteit in een zeer kleine ruimte

Snelle inbedrijfstelling – vooringestelde instrumenten

Automatisch herstel van gegevens voor onderhoud

Video's

-

Eenvoudige producten

- Gemakkelijk te selecteren, installeren en gebruiken

Technische topkwaliteit

Eenvoud

-

Standaardproducten

- Betrouwbaar, robuust en onderhoudsarm

Technische topkwaliteit

Eenvoud

-

Gespecialiseerde producten

- Ontworpen voor veeleisende applicaties

Technische topkwaliteit

Eenvoud

Variabel

| FLEX selectie | Technische topkwaliteit | Eenvoud |

|---|---|---|

Fundamental selectie Voldoe aan uw basismeetvoorwaarden |

Technische topkwaliteit

|

Eenvoud

|

Lean selectie Beheers eenvoudig uw belangrijkste processen |

Technische topkwaliteit

|

Eenvoud

|

Extended selectie Optimaliseer uw processen met innovatieve technologieën |

Technische topkwaliteit

|

Eenvoud

|

Xpert selectie Beheers uw meest uitdagende applicaties |

Technische topkwaliteit

|

Eenvoud

Variabel |

-

-

Technische informatie (TI)

CNGmass

Coriolis flowmeter

EN NL 15/03/202301/02/2014Taal:

Engels

Versie:

15/03/2023

Bestandsgrootte:

2.1 MB

Bestandsnaam:

TI01142DEN_0223-00.pdf

-

-

-

Bedieningshandleiding (BA)

CNGmass Modbus RS485 Operating Instructions

Coriolis flowmeter

EN NL 01/02/2014Taal:

Engels

Versie:

01/02/2014

Bestandsgrootte:

2.2 MB

Bestandsnaam:

BA01283DEN_0114.pdf

-

-

-

Instrumentparameters (GP)

CNGmass Modbus RS485 Description of Device Parameters

Coriolis flowmeter

EN NL 23/12/2015Taal:

Engels

Versie:

23/12/2015

Bestandsgrootte:

921.6 KB

Bestandsnaam:

GP01025DEN_0115.pdf

-

-

-

Beknopte instructie (KA)

CNGmass Brief Operating Instructions

Coriolis flowmeter

EN NL 18/09/201531/12/201401/02/2014Taal:

Engels

Versie:

18/09/2015

Bestandsgrootte:

1.2 MB

Bestandsnaam:

KA01170DEN_0315.pdf

-

-

-

Montage-instructies (EA)

Electrical trace heating systems

Promass 100, 200, 300, 500, 500-digital, LNGmass, CNGmass, LPGmass

EN NL 01/03/2021Taal:

Engels

Versie:

01/03/2021

Bestandsgrootte:

883.1 KB

Bestandsnaam:

EA01339DA2_0121.pdf

-

-

-

Montage-instructies (EA)

EA Replacing Small parts

Proline 10, 100, 400, 800 Index C, 500, 500-digital, CNG-, LNG-, LPGmass

EN NL 01/01/202401/05/202101/04/202131/07/202002/08/2019Taal:

Engels

Versie:

01/01/2024

Bestandsgrootte:

518.1 KB

Bestandsnaam:

EA01119DA2_0923-00.pdf

-

-

-

Montage-instructies (EA)

Safety Instructions for Spare Parts Installation Instructions

Flowmeter

EN NL 01/03/201828/11/201325/04/2013Taal:

Engels

Versie:

01/03/2018

Bestandsgrootte:

139.5 KB

Bestandsnaam:

EA01051DA2_0318.pdf

-

-

-

Montage-instructies (EA)

EA Replacing Spare Parts

CNG-, LNG-, LPGmass, Proline 100, 300, 400 Index C, 500, 500-digital

EN NL 01/01/202415/12/202101/06/202101/06/202002/08/2019Taal:

Engels

Versie:

01/01/2024

Bestandsgrootte:

1.9 MB

Bestandsnaam:

EA01018DA2_1523-00.pdf

-

-

-

Ex-veiligheidsinstructie (XA)

XA CNGmass

INMETRO:

Zone 1

Zone 21EN NL 27/04/202314/11/2014Taal:

Engels

Versie:

27/04/2023

Bestandsgrootte:

451.5 KB

Bestandsnaam:

XA01253DEN_0423-00.pdf

-

-

-

Ex-veiligheidsinstructie (XA)

CNGmass

ATEX:

II2G

II2D

IECEx:

Zone 1

Zone 21EN NL 15/09/202210/11/201401/02/2014Taal:

Engels

Versie:

15/09/2022

Bestandsgrootte:

585.9 KB

Bestandsnaam:

XA01251DEN_0322-00.pdf

-

%20-%20PP01.jpg)

%20-%20CS01637X.jpg)